Good At Learning, Good At Innovation

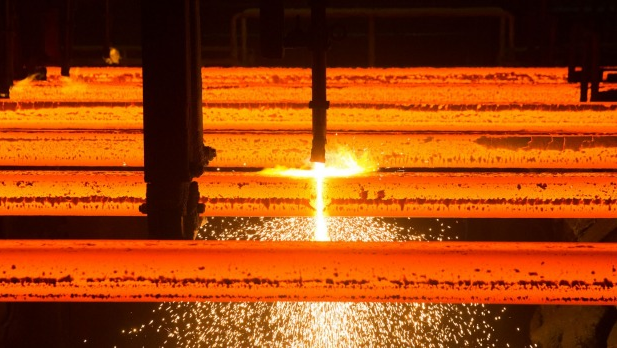

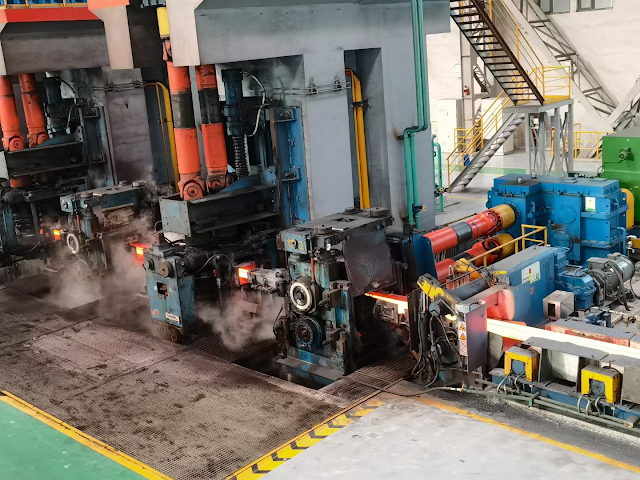

Chinese famous person, Deng Xiaoping visited Baosteel and the inscription "master new technology, be good at learning, but also to be good at innovation." Development of iron and steel enterprises does not stay in the introduction, but in the production process, constantly on the production line diagnosis, and then determined for technological transformation. This transformation is sometimes multiple times, and each time the transformation is innovation and progress. Learning and innovation--important quality should maintain in the bad market situation, we should do our best to improve our steel rolling mill equipment , make high-quality rolling machines, and improve our competitive advantage. Combined with the company for many years of practical experience in the field of complete sets of steel rolling mill equipment. Creative developed suitable rolling mills for small and medium enterprises, rolling products for multi-species, multi-standard high-speed wire rods, and re-bar

.jpg)