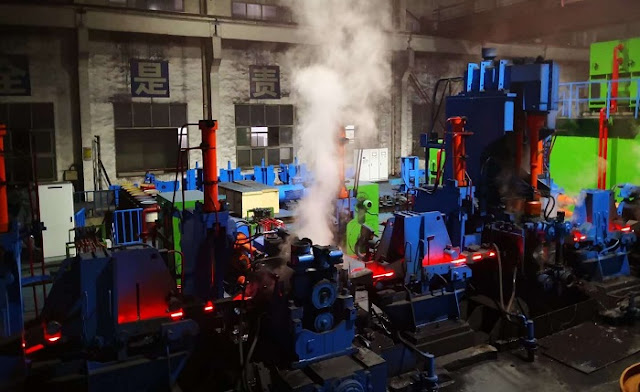

Hot Rolling Mill: 50,000 -300,000 TPY of Bar Rolling Mill

Full Continuous Rolling 50,000 -300,000 TPY of Bar Rolling Mill Production Line.

Finished bar size: 8-32mm

Raw Material: common carbon steel, high-quality carbon structural steel, and low alloy steel

The designed annual production capacity is 50,000 -300,000 tons.

The maximum rolling speed of finishing mill is 5-16 m/s.

1. Billet

The whole continuous rolling production line uses 100 x 100-150 x 150 continuous casting billet as raw material, with a length of 3000 mm-6000 mm, all provided by the company's internal steelmaking and continuous casting workshop.

2. A new regenerative push-steel reheating furnace is built in the full tandem rolling production line. The fuel is natural gas or blast furnace gas, and the air is preheated singly. The hourly heating capacity is 40-80 t/h, end-in, and side-out, single-row material distribution, meeting the annual production requirements of 50,000 -300,000 tons of rolling. Reheating furnace chamber size 6.6X24m.

3. Sixteen rolling mills are used, which are divided into roughing, intermediate and finishing rolling units, forming a full tandem rolling production line. The layout type is 6+6+4 horizontal and vertical alternation. The main drive of the rolling mill is controlled by full digital PLC. Micro-tension continuous rolling is used in rough and medium rolling. There is one looper in the middle of medium rolling and finishing rolling. There are vertical loopers between each rolling mill of finishing rolling mill, forming tension-free and torsion-free rolling. The maximum speed of the mill can reach 5-16m/s.

4. There are three flying shears on the rolling mill line, which are located behind the three units. They are used for cutting head, accident breaking and product size dividing. The shear structures are crank type, rotary type, and crank rotary combination type respectively.

5. Rolling process: disc 6.5mm, threaded steel 8-32mm. The annual production of 50-300,000 tons of materials requires 330,000 tons of continuous casting slab, and the overall yield is 98% (considering negative deviation).

6. Set up water cooling device for controlled rolling in front of finishing mill and water cooling device for controlled cooling behind finishing mill to produce high strength steel bar (grade 3 steel) and improve mechanical properties of products.

7. Semi-automatic packing equipment and 50 tons of cold shear are used in the finishing collection area.

8. The control system adopts computer secondary control, which is divided into four zones (heating furnace zone, rolling zone, cooling control zone, and finishing zone). Each control point is decentralized and centralized.

If you are interesting, Pls contact me:

E-mail: Stella@hanrm.com

Whatsapp/Wechat:+8615877652925

Website: https://www.hanrm.com

Finished bar size: 8-32mm

Raw Material: common carbon steel, high-quality carbon structural steel, and low alloy steel

The designed annual production capacity is 50,000 -300,000 tons.

The maximum rolling speed of finishing mill is 5-16 m/s.

1. Billet

The whole continuous rolling production line uses 100 x 100-150 x 150 continuous casting billet as raw material, with a length of 3000 mm-6000 mm, all provided by the company's internal steelmaking and continuous casting workshop.

2. A new regenerative push-steel reheating furnace is built in the full tandem rolling production line. The fuel is natural gas or blast furnace gas, and the air is preheated singly. The hourly heating capacity is 40-80 t/h, end-in, and side-out, single-row material distribution, meeting the annual production requirements of 50,000 -300,000 tons of rolling. Reheating furnace chamber size 6.6X24m.

3. Sixteen rolling mills are used, which are divided into roughing, intermediate and finishing rolling units, forming a full tandem rolling production line. The layout type is 6+6+4 horizontal and vertical alternation. The main drive of the rolling mill is controlled by full digital PLC. Micro-tension continuous rolling is used in rough and medium rolling. There is one looper in the middle of medium rolling and finishing rolling. There are vertical loopers between each rolling mill of finishing rolling mill, forming tension-free and torsion-free rolling. The maximum speed of the mill can reach 5-16m/s.

4. There are three flying shears on the rolling mill line, which are located behind the three units. They are used for cutting head, accident breaking and product size dividing. The shear structures are crank type, rotary type, and crank rotary combination type respectively.

5. Rolling process: disc 6.5mm, threaded steel 8-32mm. The annual production of 50-300,000 tons of materials requires 330,000 tons of continuous casting slab, and the overall yield is 98% (considering negative deviation).

6. Set up water cooling device for controlled rolling in front of finishing mill and water cooling device for controlled cooling behind finishing mill to produce high strength steel bar (grade 3 steel) and improve mechanical properties of products.

7. Semi-automatic packing equipment and 50 tons of cold shear are used in the finishing collection area.

8. The control system adopts computer secondary control, which is divided into four zones (heating furnace zone, rolling zone, cooling control zone, and finishing zone). Each control point is decentralized and centralized.

If you are interesting, Pls contact me:

E-mail: Stella@hanrm.com

Whatsapp/Wechat:+8615877652925

Website: https://www.hanrm.com

评论

发表评论