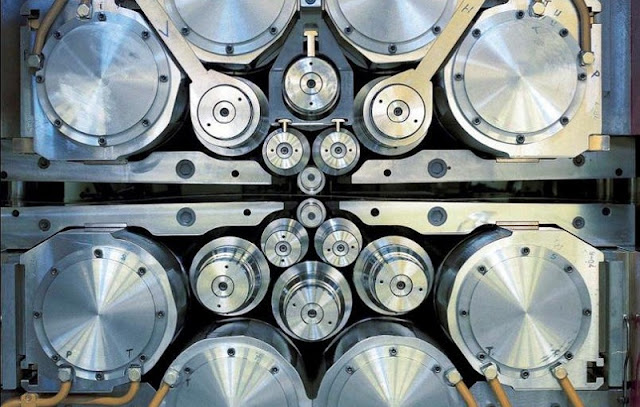

Sendzimir 20 High Mill

Sendzimir 20 High Mill

The essential difference between Sendzimir cold rolling mill and four high rolling mill or other types of rolling mill is the different transmission direction of rolling force. The rolling force of the Sendzimir cold rolling mill is transferred from the work roll to the backup roll device through the intermediate roll, and finally to the solid overall stand. This design ensures the support of the work roll in the whole length direction. In this way, the roll system deformation is very small, and the very accurate thickness deviation can be obtained in the whole width direction of rolling.

Sendzimir mill has the following main characteristics in structure and performance

(1) The frame with integral casting (or forging) has high rigidity, and the rolling force acts radially on each section of the frame.

(2) The work roll diameter is small, and the pass reduction rate is large, up to 60%. Some materials can be rolled into very thin strips without intermediate annealing.

(3) It has axial and radial roll shape adjustment, roll diameter size compensation, rolling line adjustment, and other mechanisms, and adopts hydraulic screw-down and hydraulic AGC system, so the product has good shape and high dimensional accuracy.

(4) The quality of the equipment is light, and the quality of the rolling mill is only one-third of that of the four high rolling mills of the same specification. The rolling mill has a small size and needs less capital investment.

Sendzimir cold rolling mill is basically a single stand reversible layout, with large flexibility and a wide range of products. However, there are also very few Sendzimir mills with continuous arrangements, such as a set of 1270 mm four stand fully continuous 20 high Sendzimir Mill designed and manufactured by Sendzimir in 1969 for the Zhounan plant of Nippon Steel Co., Ltd. The first mill is zr22-50 "type mill, the other three are zr21-50" type mill, rolling specification is o.3mm × 1270mm stainless steel, coil weight is 22T, rolling speed is 600m / min.

The form and nomenclature of the Sendzimir cold rolling mill are introduced as follows:

The most commonly used Sendzimir cold rolling mill is 1-2-3-4 20 high mill. For example, zr33-18 ", Z" is the first letter of zimna in Polish, which means "cold"; "R" means "reversible"; "33" means the model of the rolling mill; "18" means the number of inches of rolled strip width. Sendzimir cold rolling mill also has 1-2-3 12 high mill, but 1-2-3 Sendzimir cold rolling mill is no longer manufactured after 1964.

The 1-2 six high mills of Sendzimir cold rolling mill consists of two driven work rolls and four backing bearing rolls,

For example, zs06, "s" stands for "plate", which is used to roll wide plates, but it can also roll strip, and some are also used in the continuous processing line.

At present, the development level of the Sendzimir mill is as follows:

(1) Maximum width of rolled strip. At present, the widest rolling strip is a zr22-80 rolling mill in France. The maximum rolling width is 2032mm for mild steel and silicon steel, and the thickness deviation is ± 0.005mm.

(2) Minimum thickness of rolled strip. The minimum thickness of rolled strip is related to its width and steel grade. The minimum thickness of American rolled silicon steel is 0.002mm and its width is 120mm. When rolling stainless steel in Japan, the minimum thickness is 0.127mm when the width is 1220mm; when the width is 200mm, the minimum thickness is 0.01mm; when rolling non-ferrous metals, the minimum thickness is 0.0018mm (zr32-4 1 / 4 type, rolled red copper).

(3) Rolling speed. The maximum rolling speed of zr21-44 mill for low carbon steel in the United States is 1067m / min, and that of zr21 mill for silicon steel and stainless steel in the United States and Japan is 800m / min.

A complete set of 20 high Sendzimir Mill generally includes the working stand, coiler, decoiler, feeding mechanism, AGC system, hydraulic system, cooling system, oil fume exhaust system, etc.

Website: https://www.hanrm.com

Laying Head of Wire Rod Mill

评论

发表评论