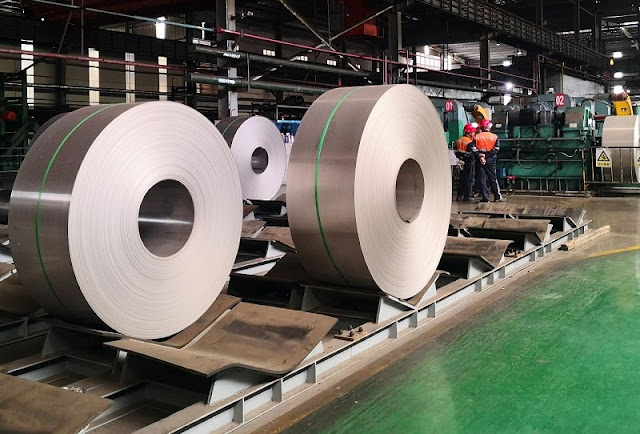

Difference Between Hot Rolled and Cold Rolled Stainless Steel

Difference Between Hot Rolled and Cold Rolled Stainless Steel

Both hot rolling and cold rolling are processes for forming section steel or steel plate. They have a great influence on the structure and properties of Bai steel. The rolling of steel is mainly hot rolling, and cold rolling is only used to produce small section steels and thin plates.

Hot Rolling

Advantages:

It can destroy the casting structure of the steel ingot, refine the grain of the steel, and eliminate the defects of the microstructure so that the steel structure is dense and the mechanical properties are improved. This improvement is mainly reflected in the rolling direction so that the steel is no longer isotropic to a certain extent; bubbles, cracks, and looseness formed during casting can also be welded under high temperature and pressure.

Disadvantages:

1. After hot rolling, the non-metallic inclusions (mainly sulfides and oxides, as well as silicates) inside the steel are pressed into thin sheets, and delamination (interlayer) occurs. Delamination greatly deteriorates the tensile properties of the steel in the thickness direction, and it is possible that interlayer tearing may occur when the weld shrinks. The local strain induced by weld shrinkage often reaches several times the yield point strain, which is much larger than the strain caused by the load;

2. Residual stress is caused by uneven cooling. Residual stress is the internal self-balanced stress without external force. Hot-rolled steel sections of various cross-sections have such residual stresses. Generally, the larger the section size of the steel section, the larger the residual stress. Although the residual stress is self-balanced, it still has a certain influence on the performance of the steel member under the action of external force. For example, it may have adverse effects on deformation, stability, fatigue resistance, etc.

Cold Rolling

Cold rolling refers to the processing of steel plates or strips into various types of steel through cold drawing, cold bending, and cold drawing at room temperature.

Advantages: fast forming speed, high output, and does not damage the coating, can be made into a variety of cross-sectional forms to meet the needs of the use conditions; cold rolling can cause large plastic deformation of the steel, thereby improving the yield of the steel point.

Disadvantages:

1. Although there is no thermal plastic compression during the forming process, there are still residual stresses in the section, which will inevitably affect the overall and local buckling characteristics of the steel;

2. The cold-rolled steel style is generally an open section, which makes the section free The torsional stiffness is low. It is prone to torsion during bending and bending and torsion buckling is likely to occur under compression, and the torsion resistance is poor;

3. The wall thickness of cold-rolled steel is small, and there is no thickening at the corners where the plates are connected, which bears localized The ability to concentrate loads is weak.

The Main Difference Between Hot Rolling and Cold Rolling is:

1. The cold-rolled formed steel allows local buckling of the section, so that the bearing capacity of the bar after buckling can be fully utilized; while the hot-rolled steel does not allow local buckling of the section.

2. Hot-rolled steel and cold-rolled steel have different causes of residual stress, so the distribution on the cross-section is also very different. The residual stress distribution on the section of cold-formed thin-walled steel is curved, while the residual stress distribution on the section of hot-rolled or welded steel is thin-film.

3. The free torsion stiffness of hot-rolled steel is higher than that of cold-rolled steel, so the torsion resistance of hot-rolled steel is better than that of cold-rolled steel.

Usually, the hot rolling lubricant is delivered to the surface of the roll in the form of a mixture of oil and water. Water is the carrier, and a small amount of oil is evenly dispersed in the water. The action process of the oil-water mixture is the transformation process from the oil-in-water phase to the water-in-oil phase.

After the mixed liquid reaches the roll surface, it spreads quickly on the roll surface in the form of oil-in-water. When it enters the deformation zone and contacts the high-temperature rolling piece, due to the effect of temperature and pressure, the water quickly evaporates and transforms into a water-in-oil phase.

A part of the oil is burned into a combustible mainly composed of ash; a part of the oil is evenly covered in the form of an oil film on the contact arc surface of the roll and the rolling piece, and both can be lubricated within about 0.01s in the deformation zone.

Cold rolling is a steel sheet that is further thinned to the target thickness of No. 1 steel sheet under room temperature conditions.

Compared with hot-rolled steel sheets, cold-rolled steel sheets are more accurate in thickness and have a smooth and beautiful surface.

At the same time, they also have various superior mechanical properties, especially in terms of processing properties. Because cold-rolled raw coils are relatively brittle and hard, and not suitable for processing, cold-rolled steel sheets are usually required to be annealed, pickled, and the surface smoothed before being delivered to customers. The maximum thickness of cold-rolled is 0.1-8.0mm or less.

For example, the thickness of cold-rolled steel plates in most factories is less than 4.5mm; the minimum thickness and width are determined according to the equipment capacity of each factory and market demand.

Stainless steel cold-rolled steel plates are stainless steel plates produced by cold-rolling processes. Those with a thickness less than 3mm are thin plates, and those with a thickness greater than 3mm are thick plates. It is used to make corrosion-resistant parts, pipelines, containers, medical equipment, marine equipment, etc. of the petroleum and chemical industry. Its classification and designation are as follows:

1. Austenitic steel

In addition to the same as the hot-rolled part (29 kinds), there are (1) 2Cr13Mn9Ni4(2) 1Cr17Ni7(3) 1Cr17Ni8

2. Austenitic-ferritic steel

Except the same as the hot-rolled part (2 kinds), there are (1) 1Cr18Ni11Si4AlTi(2) 1Cr21Ni5Ti

3. Ferritic steel

Except the same as the hot-rolled part (9 kinds), there are also: 00Cr17

4. Martensitic steel

In addition to the same as the hot-rolled part (8 types), there are 1Cr17Ni2

5. Precipitation hardening section steel: same as the hot-rolled part

Please contact stella@hanrm.com for a quotation.

And free send inquiry to us.

Email: stella@hanrm.com stellarollingmill@gmail.com

Whatsapp/Wechat:+8615877652925

More News You May Interesting:

Hot Rolled Steel and Cold Rolled Steel

Hot Rolled Steel Plate VS Cold Rolled Steel Plate

Finishing Rolling Mill Process Explanation

Reasons and Solutions for the Piling of Wire Rod Rolling

Characteristics and Quality of Wire Rod

Morgan Wire Rod Mill

Why does the Steel Bar Bend after being Cut by Flying Shear?

Headless Welding Rolling Process

Bar Rolling Mills Water Cooling Technology

How to Improve the Thermal Efficiency of the Reheating Furnaces?

Causes of Surface Cracks in High-Speed Wire Rod Rolling Mill

What is Slit Rolling?

Failure Analysis of Cold Mill Roll

Causes and Solution of Steel Piling-up in High-speed Wire Rod Rolling Mills?

Bar Automatic Counting System

Rolling Mill Pass Design

评论

发表评论