Technical Specification for Bar Mill Walking Beam Cooling Bed

Technical Specification for Bar Mill Walking Beam Cooling Bed

1. Service Environment and Conditions of Equipment

Ambient temperature: - 20 - + 40 ℃ relative humidity:

Working environment: not applicable to inflammable and explosive altitude: + 108 M

2. Technical Requirements

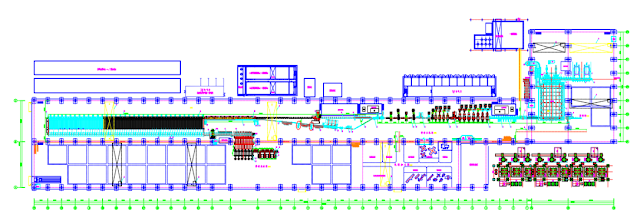

2.1 Incoming direction: left feeding, see the document library of equipment layout plan in the cooling bed area

1 - finished rolling mill 2 - finished flying shear 3 - acceleration roller table 4 - step cooling bed 5 - cold shear 6 - sizing machine

2.2 Technical Parameters

2.2.1 Acceleration Roller Table

Roll Diameter: Φ 188mm, roll length: 190mm, roll distance: 1200mm, transmission type: single machine transmission, variable frequency speed regulation, irreversible; roller linear speed: 4.5 ~ 20m / s, roller length: ~ 30000mm, motor: yvpg100l2-4, 2.2kW, 1500rpm, AC380V, axial flow fan at the end of each motor: 125fzy2-s, 25W, 220V, 50Hz, the last six rollers are installed at an inclination of 1 ° ~ 12 °. Quantity: 24 sets.

2.2.2 Step-by-Step Cooling Bed (Walking Beam Cooling Bed)

(1) Application: it is arranged at the back of the rolling mill for the cooling of section steel and bar products. Cooling finished product specification Φ10-40mm deformed steel, Φ 10-50mm round steel. The steel grades are ordinary carbon steel, high-quality carbon steel, and low-alloy steel, with a maximum finished product speed of 16m / s and an annual production capacity of 600000 tons.

(2) The type is rack stepping type, the effective size of the cooling bed surface is 96000 × 9500mm, and the maximum allowable steel length is 90 m, pitch 100 mm, rack thickness is 18 mm, static rack spacing 300 / 600 mm, dynamic rack spacing 300 / 600 mm.

(3) Input roller table: roller diameter Φ 188mm, roller length 190mm, roller distance 1200mm, inclination 12 °, transmission

The motor is driven by a single machine, and frequency conversion and speed regulation, are irreversible, the linear speed of the roller is 4.5 ~ 20m / S (max), motor yvpg100l2-4, 2.2kW, 1500rpm, each motor is equipped with axial flow fan 125fzy2-s, 25W, 220V, 50Hz at the end, with a quantity of 115; 6 free rollers.

(4) Transfer in mechanism: the width of the block is 150 mm, the length of the block is 138 m, the angle between the block and the horizontal 35 °, the angle between the transfer block and the vertical is 12 °, the lifting speed of the transfer block is 0.15-0.3m/s, the lifting of the transfer block adopt hydraulic cylinder Φ 63 / Φ 45x90.

(5) Bed surface drive: main motor z4-280-21132kw, rotating speed 750 / 1600rpm, 2 sets; photoelectric encoder LAKESHORE, 2 pieces; reducer a = 508mm, I = 41, 4 sets; eccentricity of the eccentric wheel is 50mm. The steel stroke of the rack moving once is 100mm.

(6) Aligning roller track: roller diameter Φ 225 / 165mm, roller length 810mm, the effective number of teeth 6, the linear speed of roller surface degree v = 1.1m/s, roller spacing 1200mm; reducer bwd1.5-18-11, I = 11, motor y90l-4, 1.5KW, 1400rpm, 45 sets; the number of free rollers 18.

(7) Chain-type steel moving machine: the specification of steel transferred is ф 12 ~ ф 50mm. The maximum length of transferred steel is 90m, The layout width of the chain-type steel moving machine is 1500mm, the chain spacing is 1200mm, the chain speed is 0.2m/s, the steel shifting step distance is 20-70mm, the transmission motor ytsp160m-4, 11kw, 1500rpm, AC380V, 2 sets, the center distance of the reducer is 349mm, the transmission ratio is 1:75, the quantity is 2 sets.

(8) Transport trolley: the width of the trolley is 1000mm, the lifting time of the trolley is 1 ~ 2S, and the round-trip speed of the trolley is ~ 0.5m/s, transmission motor: ytsp132s-4, 5.5kW, 1500rpm, AC380V, 2 sets, reducer: a = 349mm, I = 1:45, 2 sets. The hydraulic cylinder is used for trolley lifting.

(9) Output roller table: roller diameter: Φ 188mm, roller length: 1000mm, roller distance: 1200mm, roller line speed: 2m / s, 86 rollers, 6 free rollers. Roller motor: ygb112l2-4, 1.5KW, 1450rpm, AC380V, 80 sets, reversible.

3. Equipment Performance Requirements

3.1.1 The structure of the cooling bed and the design of the mechanical parts shall take into account the impact force caused by the dynamic load.

3.1.2 The operation mechanism has good performance, a compact structure, and a beautiful appearance.

3.1.3 The motor has enough overload coefficient and can work normally underrated ambient temperature.

3.1.4 The product shall have more than two years' operation performance of similar projects.

4. Equipment Manufacturing Requirements

4.1 Technical standards, process specifications, and quality standards of the equipment shall be strictly in accordance with relevant standards. Party B shall provide Party A with manufacturing, assembly, and inspection standards.

4.2 After Party B completes the construction drawing design, Party B shall notify Party A to send personnel to Party B for design liaison one week in advance, Party B shall make design disclosure to Party A, the drawings of key parts shall be approved by Party A, and both parties shall sign the design review minutes.

4.3 Party A has the right to change the design without a significant impact on the price, progress, and process. Party B shall not refuse the design change request put forward by Party A in any form. 4.4 the materials selected by Party B must meet the standard requirements, and Party B must provide a material certificate, product qualification certificate, and flaw detection report for the materials of key parts considered by Party A. If alternative materials are selected, the material performance shall not be lower than the original design and shall be approved by Party A.

4.5 Any change of purchased parts shall be approved by Party A.

4.6 Party B shall be responsible for the correctness of all drawings and data provided.

4.7 List of Purchased Parts

List of Purchased Parts of Equipment (for Reference)

>Serial number | Equipment name | Specification type |

1 | Cylinder | QGB II |

2 | Reducer | TPU |

3 | Variable frequency motor | |

4 | DC motor | |

5 | Dry oil station |

Note: All pneumatic devices include solenoid valves (DC24V) and pneumatic three components. All bearings are made in China with high-quality Pinha, WA, and Luo bearings, and requirements must be interchanged with SKF bearings.

5. Equipment and Material Requirements

5.1 Counterweight material Q235

5.2 Main drive shaft material 45 #

5.3 Rack material 16Mn

6. Equipment Appearance Requirements

6.1 Surface Treatment and Painting

(1) All external surfaces shall be treated and painted in a proper manner.

(2) At least one layer of antirust primer shall be applied to the equipment, and the surface paint shall be applied after the primer is dry.

6.2 The welding seam of the equipment must be even and flat without welding slag to ensure the welding quality.

6.3 Cleaning of equipment: before shipment, all sundries inside the parts and all traces on the internal and external surfaces shall be removed.

6.4 Equipment transportation and storage measures: the equipment must be completely dry before shipment, and all parts must be protected to avoid damage, corrosion or impurities.

6.5 The main color of the equipment is green, including the main body of the equipment, purchased main motor, etc. two months before the delivery of Party B's equipment, Party A shall notify the final color in writing and provide the color label.

7. Codes and Standards

During the period from the date of ordering to the time before Party B starts to put materials into production, if there is any modification or change due to the standards and regulations, Party A has the right to put forward supplementary requirements, which shall be solved by both parties through negotiation.

The Executive Standards of the products are as follows: l

General technical conditions for machining parts JB / zq04000.2-86 l

General requirements for welding parts JB / zq04000.3-86 l

General technical requirements for castings JB / zq04000.5-86 l

General technical requirements for assembly JB / zq04000.9-86 l

General technical conditions for coating JB / zq04000.10-86

Basic type and size of manual arc welding joint GB985-88

Precision of involute cylindrical gear gb10095-1998

Metal Brinell hardness test method gb231-1984

Metal Rockwell hardness test method gb230-1991

Paint film color and appearance test method gb1729-1991

General technical requirements for product inspection JB / zq04000.1-86

Basic test methods of low voltage apparatus gb998-1982 l

Accuracy of bevel gear and hypoid gear gb11365-1989 l

Technical conditions of metallurgical equipment Q / zt10095-1997 l

Accuracy of involute cylindrical gear gb10095-1988 l

Metal tensile test method gb228-1987 l

Other relevant standards

More News You May Interesting:

Bar Automatic Counting SystemRolling Mill Pass Design

Walking Beam Cooling Bed

Morgan Wire Rod Mill

Crank Type Flying Shear

Characteristics of Electric Arc Furnace Steelmaking

Why does the Steel Bar Bend after being Cut by Flying Shear?

Headless Welding Rolling Process

Bar Rolling Mills Water Cooling Technology

Continuous Casting Machine

How to Improve the Thermal Efficiency of the Reheating Furnaces?

Causes of Surface Cracks in High-Speed Wire Rod Rolling Mill

What is Slit Rolling?

Cardan Shaft Assembly and Routine Maintenance

Causes and Solution of Steel Piling-up in High-speed Wire Rod Rolling Mills?

评论

发表评论